Corrosion Resistant Chemical Manure Conveyor Belting

Still hesitating? Get the samples first,Contact Us!

Category

Keywords

- Detail

-

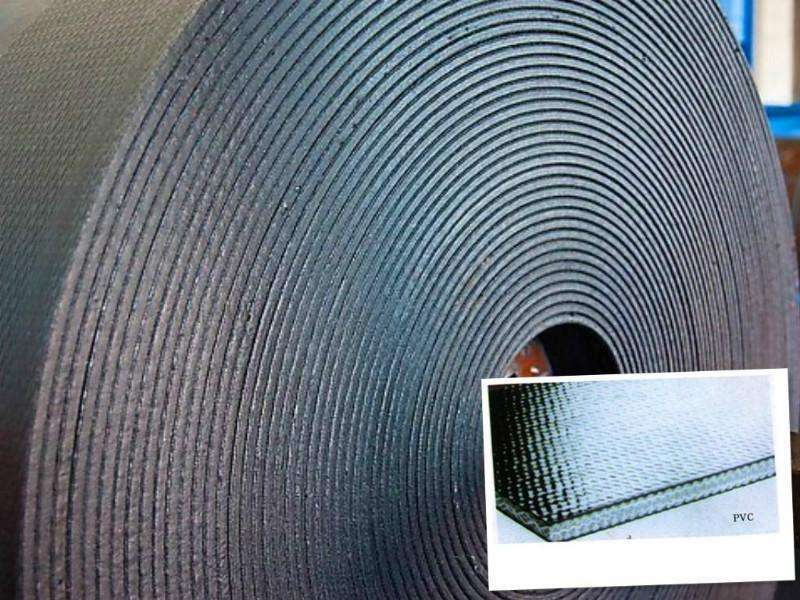

The covering layer rubber is the mixture of rubber and plastic and filled with acid resistant and alkali resistant inert materials, which is much better than LDR acid and alkali resistant conveyor belt. The framework material is EP canvas, is more reliable and more alkali resistant and the cotton canvas core belt. Generally it is made into ring shaped.

Application:

Acid & alkali resistant conveyor belt is applicable to conveying of the corrosive material containing acid and alkali in industrial and mining enterprise such as chemical plant, fertilizer plant, pulp /paper mill, cement industry, etc.

Performance of the Acid & Alkali resistant Conveyor Belt :

Performance of the Cover Layer Item Unit Indicate Tensile Strength Mpa ≥14 Rate of Elongation at break % ≥400 Abrasive wear cm ≤1.0 Acid Resistant factor 50%H2SO4,

50°C X 96 hRate of Volume expansion: ≤10% Rate of Intensity change: within -10% Adhesion Strength Cover Layer and Cloth inter layer N/mm ≥2.7 Layer of Cloth N/mm ≥2.7

Application

Power industry

Metallurgical industry

Port

Coal industry

Mine/cement

logistics transportation

About Us

Baoding elephant tape manufacturing Co., Ltd. is a professional belt production enterprises, has many years of production history of conveyor belt. Company's existing staff of 300 people, including senior technical personnel more than a dozen people and has a professional technical staff and more than 200. The company leading product is "Annai" brand conveyor belts, including general purpose fabric core conveyor belt (nylon cloth, polyester cloth core core, cotton cloth, cotton cloth core core), special purpose fabric core conveyor belt (high temperature resistant, heat resistant, flame retarding, acid and alkali resistance, oil, food, cloth a nylon cloth, polyester cloth core core, cotton cloth, cotton cloth and other core) core. Products are widely used in metallurgy, coal, coking, electricity, building materials, port, grain and so many different industries.

Related products

Anti-tearing Steel Cord Conveyor Belt

Steel Cord Conveying Belt for Rock and Stones

Rubber Cover Chevron Pattern Grain Conveyor Belt

Steel Cord Rubber Conveying Belt Manufactuer

EP Conveyor Belt for Rock Minerals Transport

Corrosion Resistant Chemical Manure Conveyor Belting

Chevron Conveyor Belt Replacement Part

Inquiry

*Attention: Please fill in the information accurately and keep communication open. We will contact you as soon as possible

WhatsApp/Wechat:

+086-13933971456

E-mail: